Hundreds of customers asked me, “how much does a custom bronze statue cost?” and then I usually give only one price (including the cost of clay molds and foundry costs). Some customers even ask me why your offer is different from others, even if it is sometimes very large. Here, I would like to talk about six factors that determine the cost of a custom bronze statue.

1.Complication of Your Design

Different designs have different complications, and different complications give us different difficulties. The more difficult your design is, the more time our artist team spends, which means more labor costs to complete. For example, if your design is for a celebrity, such as the Togolese President (our project case in 2015), rather than an enlarged decorative statue, then it will take more time from our artist team to study the background and face detail. Also, in clay mold making, it will also cost us more time than usual.

2.Artist Level

For the same custom bronze statue project, different levels of artists will give you different quality clay molds. Everyone wants high quality and high level means high cost, which is common!

3.Bronze Material

There are 2 bronze materials for custom bronze statues – bronze and brass. For bronze, we also have silicon bronze, tin bronze and recycled bronze; silicon bronze is the best bronze material for casting custom bronze statues with the best corrosion resistance. Of course, its price is also the highest. The recovered bronze is usually bought from the recycling station. They are usually scrap bronze, and no one knows the exact composition of it. For brass, we have brass with 63%-67% copper and recycled brass, the same bronze, no one knows the exact composition to recover brass. For some suppliers, they use the cheapest recycled brass instead of silicon bronze or brass.

4.Wall Thickness

The thicker of wall thickness is, the more bronze material will be used for casting, which means the cost of bronze material will be higher. But the thicker, the better welding & chasing effect it will be.

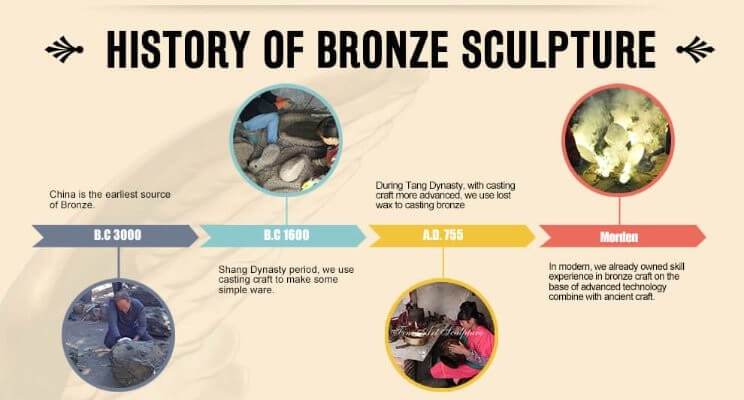

5.Casting Technique and Casting Materials

A casting is a manufacturing process in which a liquid material is typically poured into a mold containing a hollow cavity of a desired shape and then allowed to cure. The solidified part is also called the casting, which is ejected or broken through the process of completing the mold. The cast material is typically a metal or a variety of cold set materials that cure after mixing two or more components; examples are epoxy, concrete, gypsum and clay. Casting is the most commonly used to make complex shapes, otherwise it will be difficult or uneconomical to do other methods.Using High quality casting bronze!

6.Transportation and import Cost

If it is not easy to import to your country or the distance is very far, then you have to take the import cost and transportation cost into consideration. It is better to ask the supplier to quote you such kind of cost including casting cost and clay mold cost .