where to buy a custom made statue of yourself? YouFine Statues is your best choose.

- Museum quality bronze sculptures

- Competitive pricing

- Original custom work

- Reputation for quality and service

- Over 15 years in the business

- Los-Wax Casting high tech

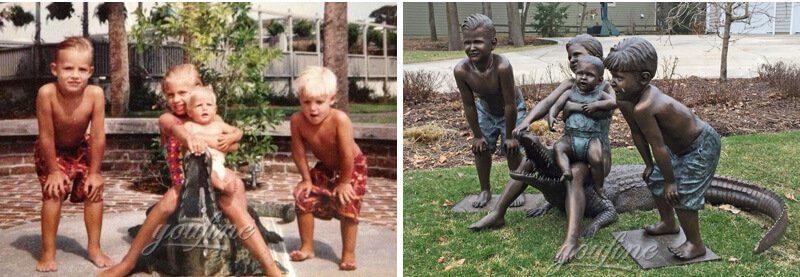

where to buy a custom made statue of yourself? how to order a custom made statue from photo? and how to make a custom made statue of yourself? let me show you the process.

The Process of a custom made staute of yourself

(1)Research and planning

The first step in creating a successful delegate work is to plan the scope of the project with our sponsors. Together we use resources (such as photos) to create sketches and scale miniatures (available for purchase).

We will discuss materials, timetables and financing here.

(2)Carving in the clay

After getting the approval to start the project, we built a steel frame called the armature, where we pasted a foam core. After sealing the foam core with latex, we are ready to start applying hundreds of pounds of hot clay to the frame.

Then, our artists spend countless hours shaping and carving every detail to produce art works of museum quality.

(3)Create mold

When the clay sculpture is complete, we begin to create the statue mold process. The clay is covered with polyurethane or silicone rubber layer and can capture every minute of detail. Plaster is applied to the outside of the mold as a ridge “sheath” to help the mold maintain its shape.

Once the mold is dry, remove the clay.

(4)Wax Replicas

The next step in our process is to use a mold to create a wax replica of the original clay sculpture. We repeat every inch of the replica, fixing any defects, such as bubbles or “shorts”.

This process is known as the Wax chase.

(5)Ceramic Shell

Once we are satisfied with the quality of the wax copy, we make the ceramic shell by immersing it in a mixture called slurry. Ceramic drying to form a hard and durable mold, can withstand the temperature of molten bronze. This is often referred to as investment casting.

The wax copy is then melted out of the ceramic.

(6)Casting the Bronze

Heat 100% U.S. bronze solid blocks to close to 2250°f temperature to pour liquid bronze into the ceramic mold.

Once the liquid bronze is poured into the ceramic shell, it is cooled for a few hours and then removed from the mold.

(7)Welding, Assembly, & Refinement

assembly and refining Once cooled and removed from the ceramic castings, the final raw pieces are welded together. The ceramic mold’s sandblasting residue and the fixed texture are a delicate process.

Then use a variety of chemicals and heat to apply surface coloring.

(8)Delivery and Installation

After the statue is completed, coordinate with our customers for transportation and installation of logistics. Finally, the finished bronze statue was ready to be unveiled.